|

As some of you may know

Billy was apprenticed in Glasgow and there learned to make furniture and

engrave glass and with those skills he came to Canada some 25 years ago

and now runs his shop and internet business from Kimberley. In fact

it is by chance that I got here just in time as in two weeks time he will

be closing the retail shop to concentrate on wholesale and internet sales

and so this will turn out to be a wee historical archive :-)

This is the outside of the shop with Billy and

Debbie at the door

And so you can see the inside of the shop

where all kinds of products are for sale and all can have clan crests,

logos and anything you want engraved or woven onto them

Clan T-Shirts are very

popular so I thought I'd follow Debbie around to see how she does it

Here you can see Debbie setting up the sewing

machine

On the wall you can see all the various

threads you can use and on the right we start making a Clan Wallace

T-Shirt

On the left picture you can see the stitch

count on the LCD display and also the progress being made with the crest

Getting there.. we are now at 7000 stitch

count

We've now gone over 9,000

An error code on the LCD screen shows a thread

has broken so Debbie needs to re-thread that and then off we go again over

the 11,000 mark

And the sewing is now complete

But of course there is always a wee thread

sticking out somewhere so the job is finished by hand. Debbie also told me

that there is a very slight mark on the T-Shirt where it is held in the

holder so this is also removed by hand during this final process.

And the finished product ready to go into a

bag and be shipped of to the customer

Of course what you don't

see are the hours of work to create the authentic graphics and digitize

them into the computer to make all this happen. I'm told depending on how

complex the design is it can take from between 11,000 to 26,000 stiches to

complete a design.

The next project I wanted

to follow was the decanter and four whisky glass boxed set. I was

most impressed with the sheer amount of work needed to complete this and

the attention to detail that goes into it. I can well understand why

some companies take a number of short cuts but due to the standards set by

Billy he simply doesn't allow anything but the highest standards and I'll

show you what I mean as we work through this process.

Billy first needs to set everything up on the

computer to interface with the laser that will cut the glass and put on

the shield. As you can see he needs to protect other parts of the glass so

a special covering has to be applied before the laser work starts.

The depth of cut is also important and here

you can see work in progress and then the complete design at the end of

the laser process

You can see how it is critical that the

decanter is positioned perfectly for the cutting process and this took

some time to set up correctly

Now this totally surprised me as I thought

with the laser cutting complete that was it but far from it. Billy

actually sands the cut to produce a smooth finish. You can see he needs to

wear special protective gloves for this and you can likely just make out

the decanter being sanded in the picture on the right. Billy tells

me that most engraved glass is in fact just laser cut and if you run a

finger over the engraving you will feel a slight roughness. This

sanding process makes it totally smooth.

Of course you do need to adjust the pressure

so that the job is done correctly. Billy showed me how easy it was to cut

a hole in the glass with this sander and it didn't take long at all so you

do need a special kind of skill to do this correctly.

And to my astonishment Billy also makes his

own boxes!

Debbie gets on with removing the masking tape

from the glasses and decanter and getting them sparkling while Billy gets

on with the presentation box. Here he is ensuring the box is at the

correct hight to get the perfect cut.

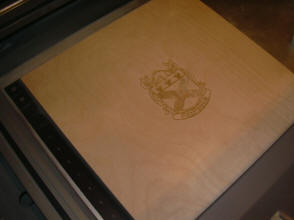

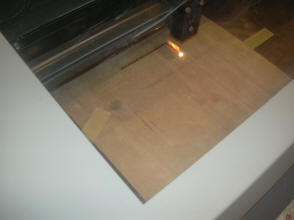

You can see the laser cutting in progress here

but again there is another surprise. To get the right depth of cut for the

box Billy does this in two passes. He found that when cut to the correct

depth with one pass of the laser you got a very slight scorching on the

wood. Due to this he decided to do a first cut to half the depth and

then repeat again to get the final cut. On the upper right you can see the

complete first cut and below the final second cut.

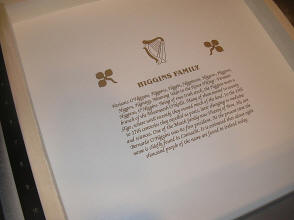

Billy now sets things up to engrave the

history of the family onto the inner lid and again it is essential the

right hight is set to get the best result.

By being engraved into the wood it should

last for generations unlike other products where they simply put it on

paper and stick it onto the lid. Just another aspect of those

special touches that make Billy's products ones to be handed down to

future generations.

The above three pictures show how the insert

for the box is done and of course will hold the glasses and decanter

firmly in the box.

Again another special touch. Billy uses

3 hinges where others use just two and even more impressive, 8 wee nails

are used to secure each hinge whereas many would use four. It's these

little details which make the finished product really special.

And a final wood polish to complete the job

And as you can see the work was not yet

complete as the product needed to be dressed and you can see the steps

above taking you through to the complete presentation.

And as you can see this presentation set was

heading for New Zealand so it had to be packed well to ensure it arrived

in tiptop condition. It was then down to doing the paperwork for shipment

and son Donald was acting as postman and was taking it down to the post

office for shipment.

So by the time you've gone

through all those steps I'm sure you'll be as amazed as I was in seeing

just how many processes you had to go through and all these extra wee

details that Billy puts into the finished product. It truly is a family

business and of very high quality.

Should you be interested in

purchasing one of those decanter sets or a T-Shirt you can visit his web

site at

http://www.familycrests.ca

And just to show what else

you can get up to how about this for a T-Shirt!

I'm getting a new logo

designed and hope to have it next week. Once it arrives I'm going to

be discussing with Debbie and Billy as to the range of merchandise I'll

put it on and what to offer. I'll include a special page on this as

you'll be able to see why certain merchandise was selected and also we'll

go through the digitising process of the logo so it can be used on various

merchandise. |